Moisture Management

Activewear Dynamics Test PTFE NanoGLIDE® Products Versus the Competition.

Moisture Management

Moisture management is the process whereby fabrics enable sweat to move from our skin through our layers and finally, into the environment.

It is a fraught journey with rounds of condensation, evaporation, and even freezing throughout. Wicking is part of how this journey is accomplished.

Garment permeability

Permeability is the ability of a garment to transport water, vapor, or air.

Constantly evolving garment technology is changing the traditional clothing design goals for permeability by increasing permeability in garments designed for highly aerobic activities.

These garments can place a premium on moisture removal at the cost of warmth when speed or wind increases.

The bottom line is that you want to achieve garment permeability that is commensurate with the moisture you will introduce for a given level of exertion.

Permeability Testing

Activewear-Dynamics (AD) laboratory equipment provides several modes of testing for water and vapor permeability.

AD drying test investigates how rapidly a garment can transport and remove liquid water. The test applies low-level heat to a wet garment. As the garment dries, the surface temperature of the garment increases, and vapor pressure beneath the garment decreases. When the garment is dry, the garment temperature will cease changing at approximately ambient temperature and the vapor pressure will equal ambient room vapor pressure. AD produces time-lapse thermal video of the drying process as well as plots of vapor pressure changes and temperature changes. The quantitative data may be used to compare the drying characteristics of fabrics, base or intermediate layers, or outer garments.

AD wicking test places a known quantity of water beneath the test garment. Low-level heating is applied. Like the drying test, AD measures the top surface temperature of the garment, temperature, and vapor pressure below the garment. The thermal imager permits AD to visualize the spread of moisture across the garment as wicking occurs. AD then observes the rate of wicking/drying and compares this characteristic across garments.

All these tests allow us to measure grams of water moved per minute.

Learn More

The Bottom Line

The AD array of tests permits them to quantify drying, wicking, and vapor transport and provide objective comparisons of competing products against PTFE.

Below are examples of drying and wicking thermal time lapse videos.

The Evidence

Drying and wicking thermal time lapse videos

TNF (left) vs XOSKIN with PTFE NanoGLIDE®

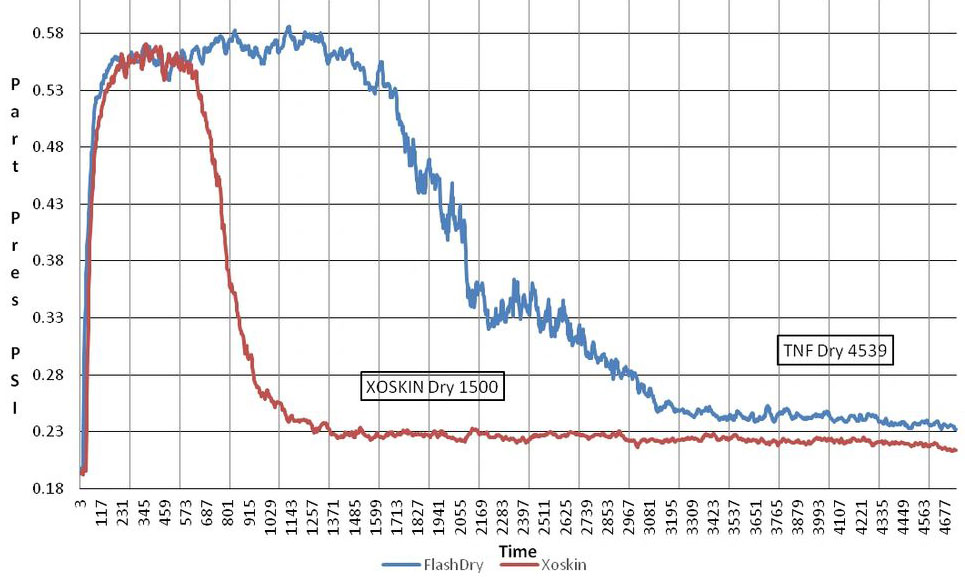

DRY TEST: TWO BASE LAYERS

This test compares drying for two base layer garments.

When the test starts, the garments are cold and show low temperatures (purple). As they dry, surface temperatures rise. When the garments are dry, the surface temperatures stabilize. The video shows a substantial difference in drying performance between the two garments.

Under Armour (left) vs XOSKIN with PTFE NanoGLIDE®

WICK AND DRY TESTING OF TWO BASE LAYERS

In this test, a water source is placed in contact with each garment at two locations.

The garments wick water from the sources until saturation is achieved. The water then begins to dry. In the end, the outline of each water source is seen, but the sources have dried to that point that wicking is no longer supported.

The left garment wicks more water than the right garment. Drying times are similar for the two, but the left garment moves more water than the right garment.

XOSKIN with NanoGLIDE®

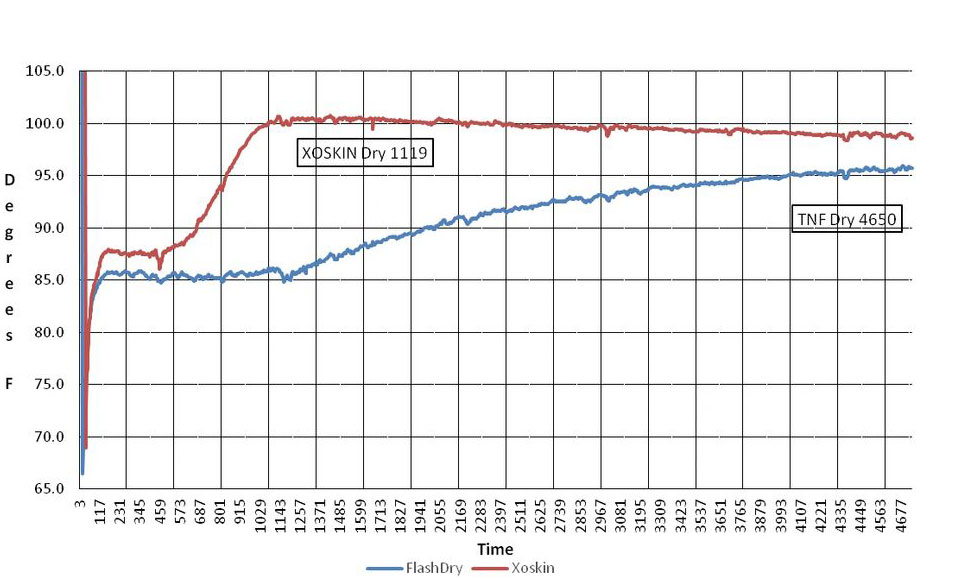

Drying Tests Quantitative Data

These tests show surface temperature and partial vapor pressure plots that correspond to the dry test video.

When the samples are dry, the temperatures and vapor pressure differentials stabilize, allowing the dry time characteristics to be recorded and compared. The plots seen below show the significantly different drying performances of the two products being compared.

Dry Test Partical Pressure

Dry Test Sample Temperature

Friction Management

Frictional forces that oppose the movement of material across the skin cause an increase of blisters, moister/sweat, chafing, and redness seen in physically active individuals.

Learn More